2021

HYDRANT-CONNECT

- On-site access to hydrant data with map view.

- Support plate with integrated NFC tag is mounted directly between hydrant number plate and hydrant upper part.

- Direct access to master data, map with neighbor hydrants and maintenance information.

STORZ-CONNECT

- Closure cap equipped with movement and position sensor to detect tampering with the hydrant or changes in position of the hydrant body.

- In the event of tampering or a change in position, the sensor triggers an alarm so that appropriate measures can be taken to prevent water theft and unauthorized tampering.

NETWORK CONTROL - NEKO

From network control to fine correlation, everything from a single source.

After an analysis of the network plan and the situation on site, the network control to be carried out is divided into sectors. The expert use of the appropriate equipment leads to an optimal result. If a leak is suspected, an immediate fine correlation is carried out.

A final report documents the results and network findings.

2020

TRENCHLESS REPLACEMENT OF THE VALVE COMMAND ROD

This non-destructive method makes it possible to replace universal command rod without trenching.

After removal, a new command rod is installed so that the operation of the valve fitting is guaranteed again.

2019

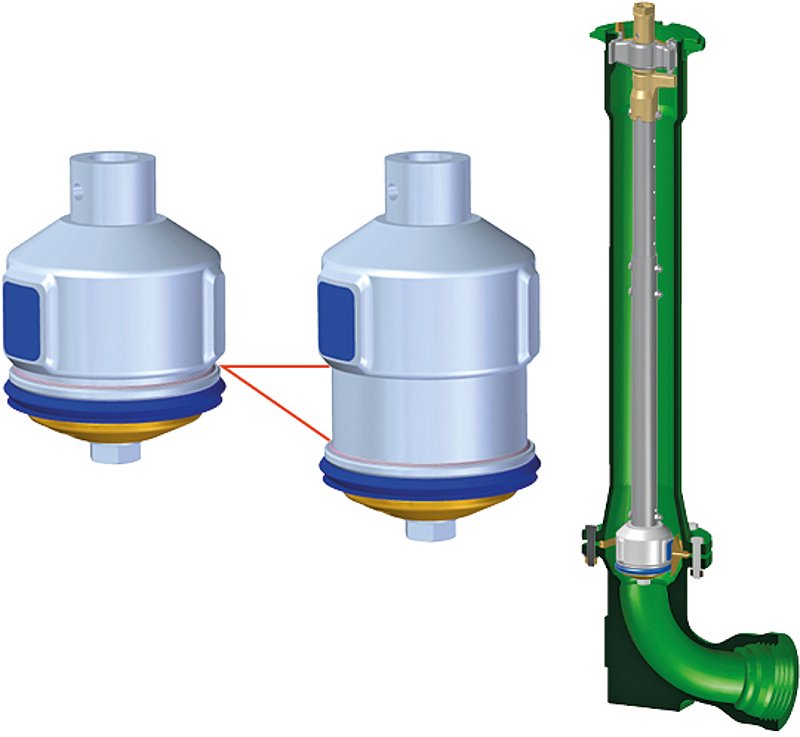

BACKFLOW PREVENTER IN THE UPPER PART 6000

- BFP integrated in the valve housing cover (2x side valve)

- Vent valve integrated in the spindle extension

- Patent pending and SVGW certified (type EA)

- Hydrant performance with BFP in the top part meets standard

- Almost no loss of performance due to BFP

BACKFLOW PREVENTER IN THE UPPER PART 6006

- BFP integrated in the hose connection

- Vent valve integrated in the spindle extension

- Patent pending and SVGW certified (type EA)

- Hydrant performance with RBFP in the upper part meets standard

2018

LORNO IN THE TRANSPORT MAIN

The modular system of LORNO is also applicable for transport mains. For this purpose, a specially developed hydrophone system is installed through a closable tapping saddle either:

– Into an already existing manhole or

– Into a shaft system specifi cally designed for this case

The radio-permeable plastic cap allows communication to the server in both variations.

2017

Hinni-upper section model 6000 - 360°

- Thanks to e new connecting system, the upper section model 6000 has the possibility of 360° orientation.

LORNO

- The continuous development and modular design of LORNO enables us to offer the LORNO Fox option for leak detection by correlation in addition to leak detection.

- Licence-free and toll-free self-organising radio network (LORNO-Net).

- SIM option: it is now also possible to connect the measuring points directly to the LCU via GSM and a data Sim card.

2016

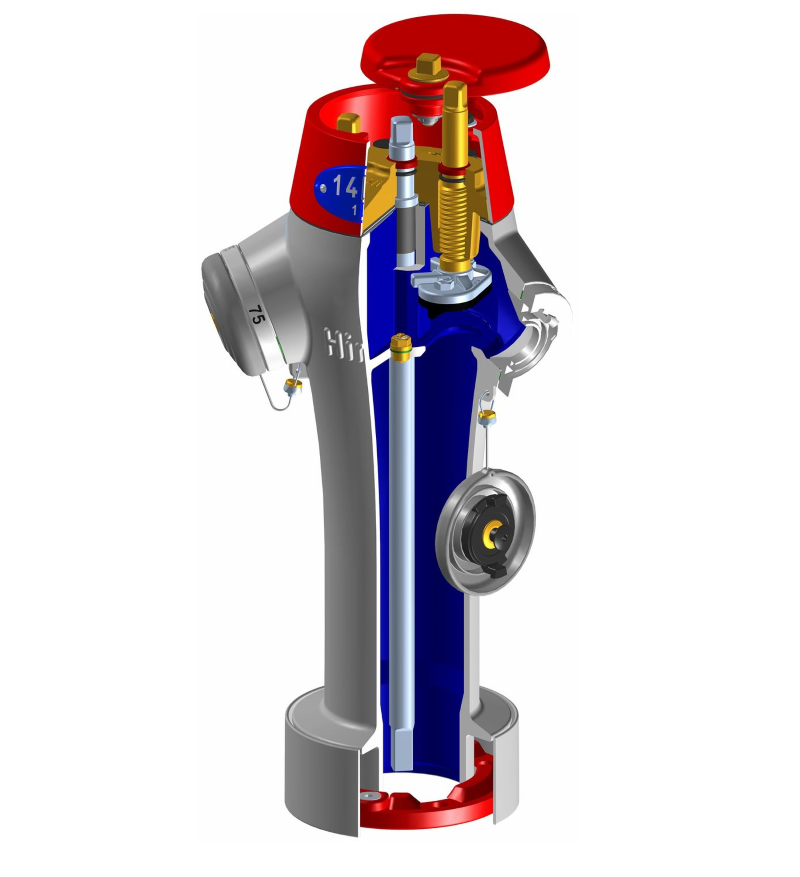

AUTOMATIC PURGE VALVE FOR HYDRANTS (PV)

Suitable for the aeration valve of the pipeline

2015

HINNI-LOWER SECTION RADIAL (LS-RADIAL)

- Adaptions to the norm SN/EN 14384

- No residual water

- Spindle bearings with a gyration stop

2014

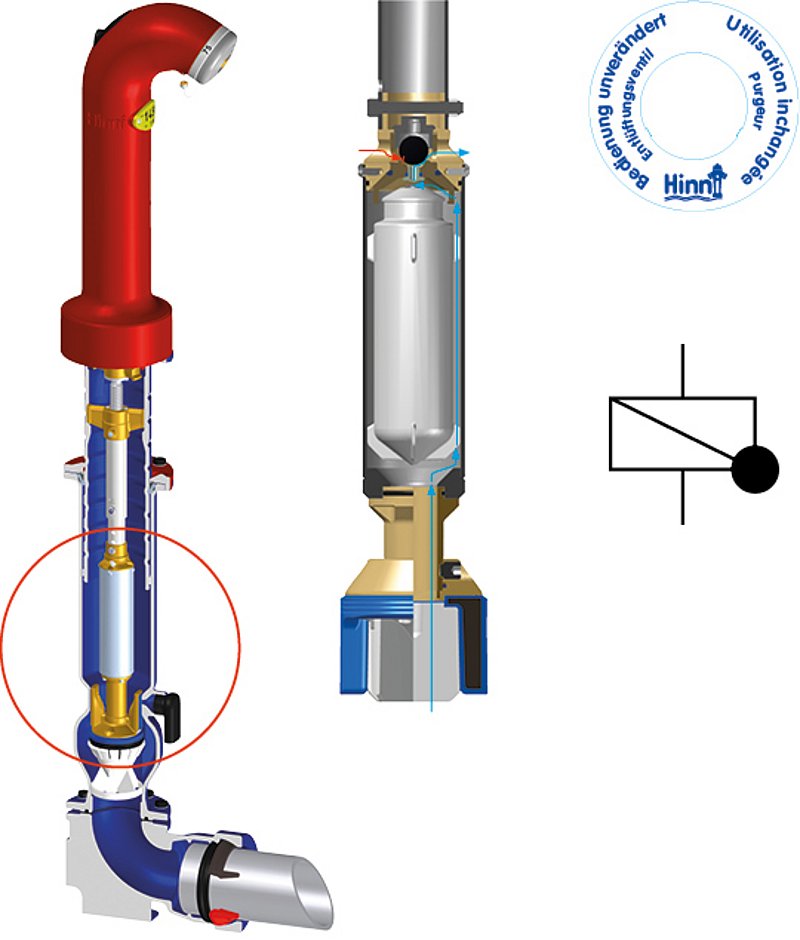

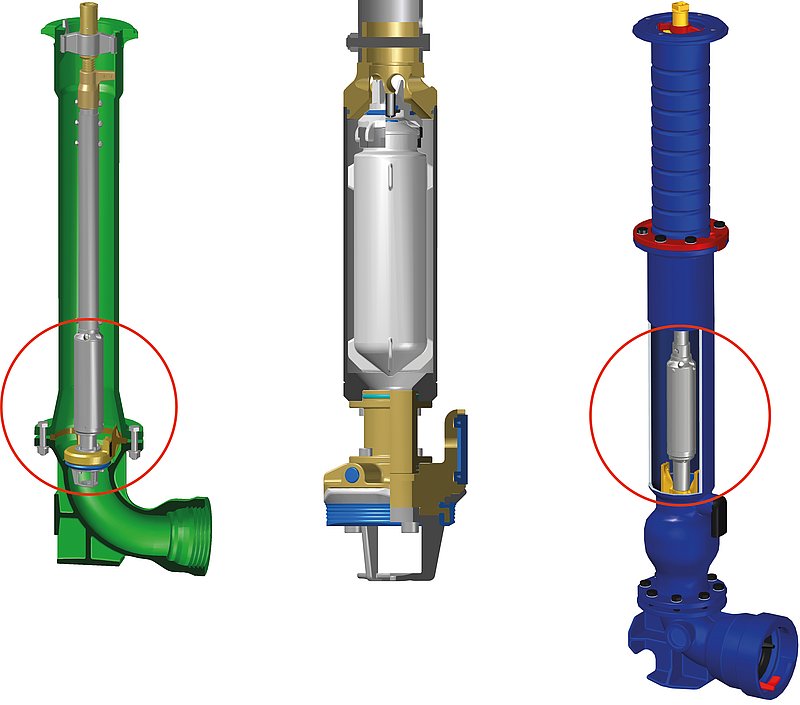

MAIN VALVE WITH BACKFLOW PREVENTER (BFP)

- Upgradeable for lower hydrant parts.

- Models: LS-ST, 4107-7502 DN 100/50

2013

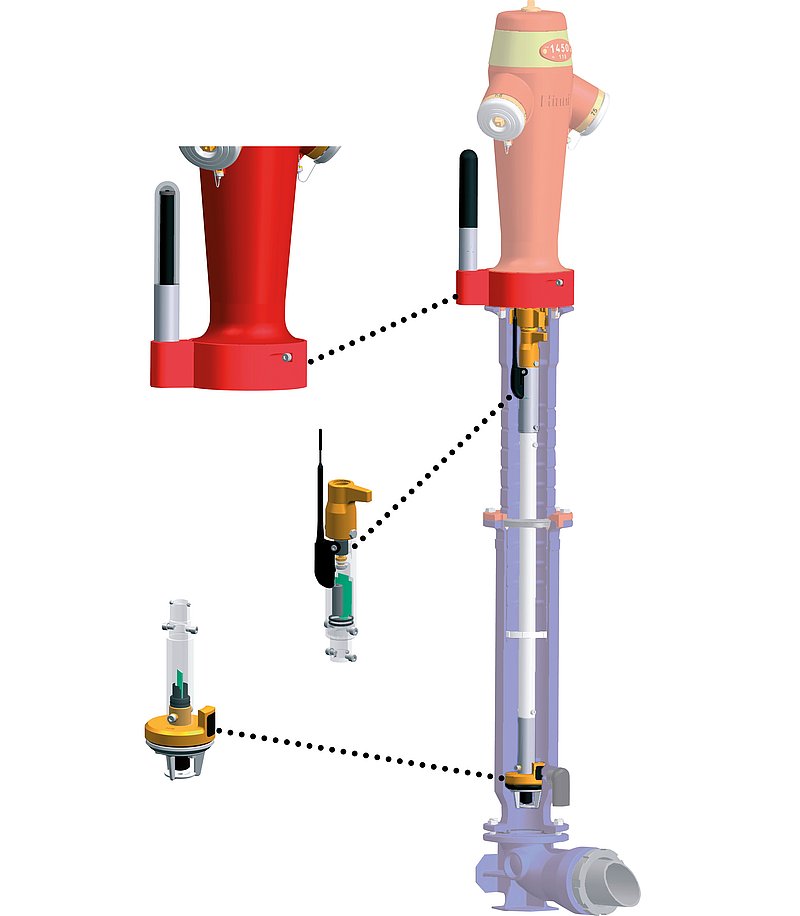

EVOLUTION OF THE LORNO-SYSTEM

- Modularity of the LORNO-system (Leak detection / water withdrawals)

- Direct access to the battery and to the measure and repeater module.

- More autonomy through new battery.

- Software for leak detection – LCU with pre-alarm and map view.

2012

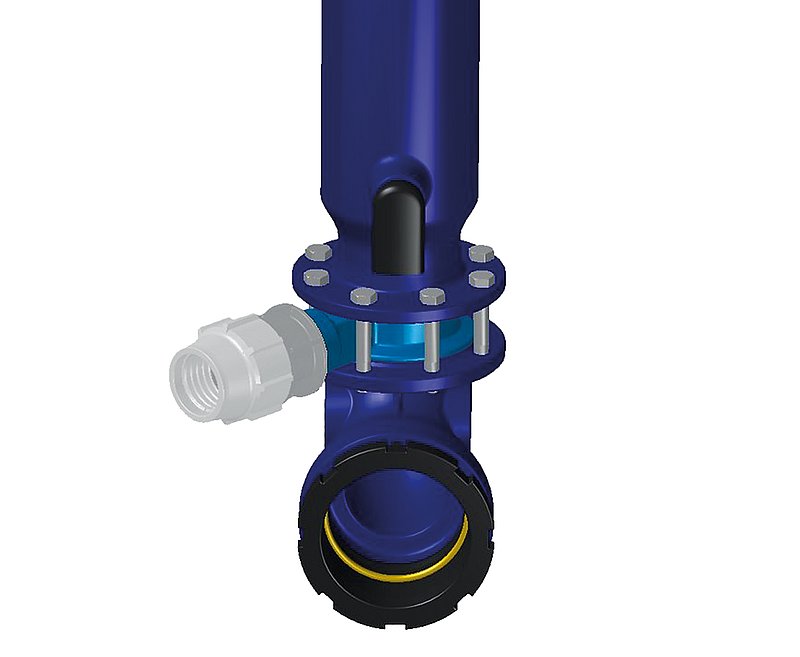

VENT AND PURGE VALVE (VPV)

Automatic vent system, to be installed into existing or new hydrants, with SVGW certification, patent is registered.

2011

REPAIR OF UNDERGROUND HYDRANTS

Repair of underground hydrants under pressure, patent registered.

LORNO ON UNDERGROUND HYDRANTS

Installation of underground hydrants at Zurich Airport where the antenna is integrated into the shaft cover.

2010

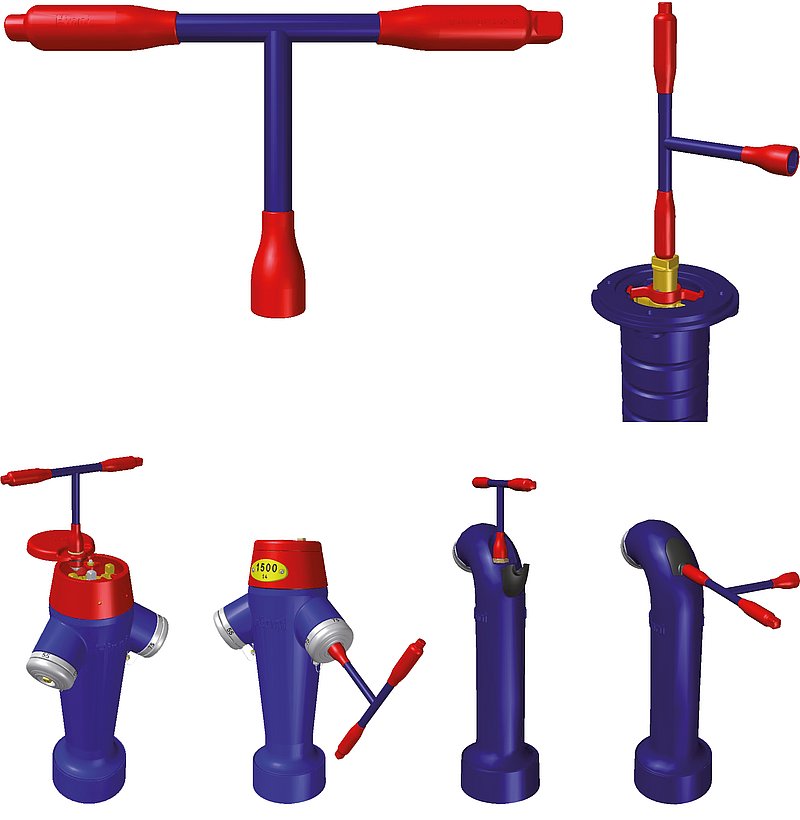

HYDRANT WRENCH

The hydrant wrench is lighter than 1kg, including an inside and outside square shaft.

- Torque up to 400Nm

- Proven PB-grips

- One grip with the front to open the protective cover OT 6006

- One grip with the outside square shaft to operate the lower parts of the hydrants during the installation, max. 100Nm

BUILDING CONNECTOR

Enamelled intermediate ring with a building connection G2‘‘. Prevents stagnant water in the hydrant supply line.

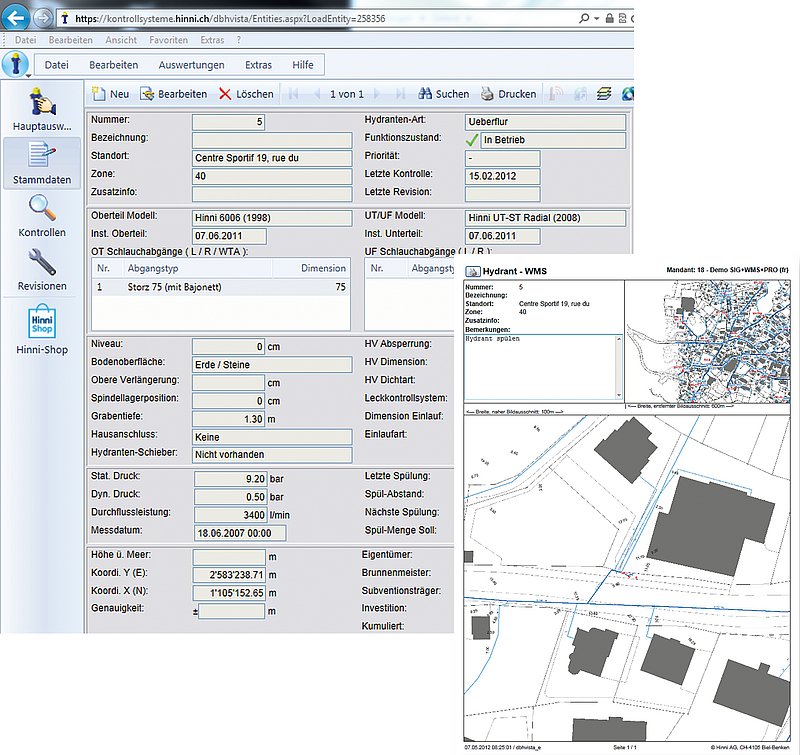

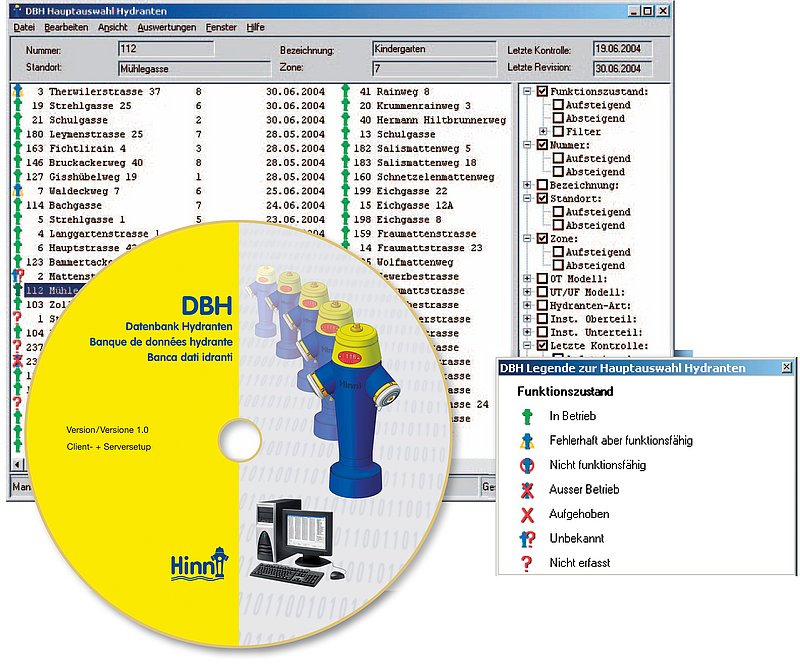

LINKING OF THE DBH-GIS/LIS

Linkage of the Hinni database with GIS/LIS through dynamic connections, WMS or WebService.

Thanks to the DBH listed data of hydrants and gate valves, holding the data in accordance with GIS/LIS is unnecessary (except for the number and the X/Y coordinates, to avoid redundancies).

2009

PROTECTIVE COVERS

New protective covers completely enamelled with a new shutter mechanism and a new design.

2008

FURTHER DEVELOPMENT OF LS-ST AND REPAIR SPECIALITIES

Dismantling of spindle bearings under upper extensions under pressure (to avoid excavation of the upper extension and interruption to the watersupply.

Development of a tool for changing the drainage cartridge in the LS 5000 model under pressure.

Lower section standard Radial (LS-ST Radial) - refitting of the LS-ST with a radial main valve.

2006

ENTRY BEND BLS

ELB-BLS – Entry bend with BLS as push security

PILLAR HYDRANTS ALL-OVER ENAMELLED

Hydrant upper section enamelled inside and outside.

2007

VALVE INSPECTION VACO AND DBH

“Valve control“ as a service by takeover of this business activity from Heinis AG (specialised in pipe construction and well master for many water suppliers in Baselland as well as partner of Hinni AG).

Expansion of the DBH for the management of the valve maintenance data.

FURTHER DEVELOPMENT OF REVISIONS UNDER FULL WATER PRESSURE

Shooting device to free drainage under pressure.

CONSTRUCTION UPPER SECTION HYDRANT

Tool to help with the installation of a lower section and/or temporary device on construction sites.

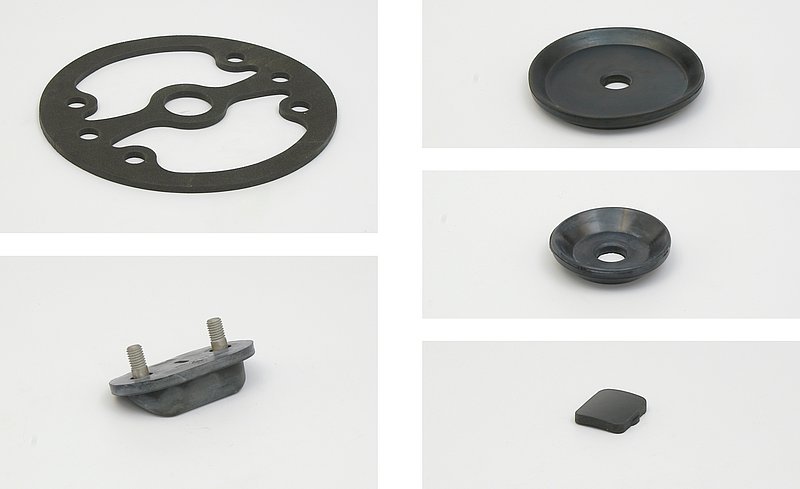

TPU – THERMOPLASTIC POLYURETHANE

Introduction of thermoplastic polyurethane as a new raw material for sealings (TPU-sealings).

2005

NETWORK MONITORING SYSTEM LORNO

A push system that monitors the potable water supply pipes through leak detection in the hydrant network, for control of water withdrawals and water levels.

COMPETENCE LEADERSHIP

Competence leadership in the hydrant production in Switzerland.

2004

DBH DATABASE HINNI

100% in-house development by Hinni AG

The database collects all information about the hydrants in a water supply sytem (master data, inspections, repair, costs of investment, etc.)

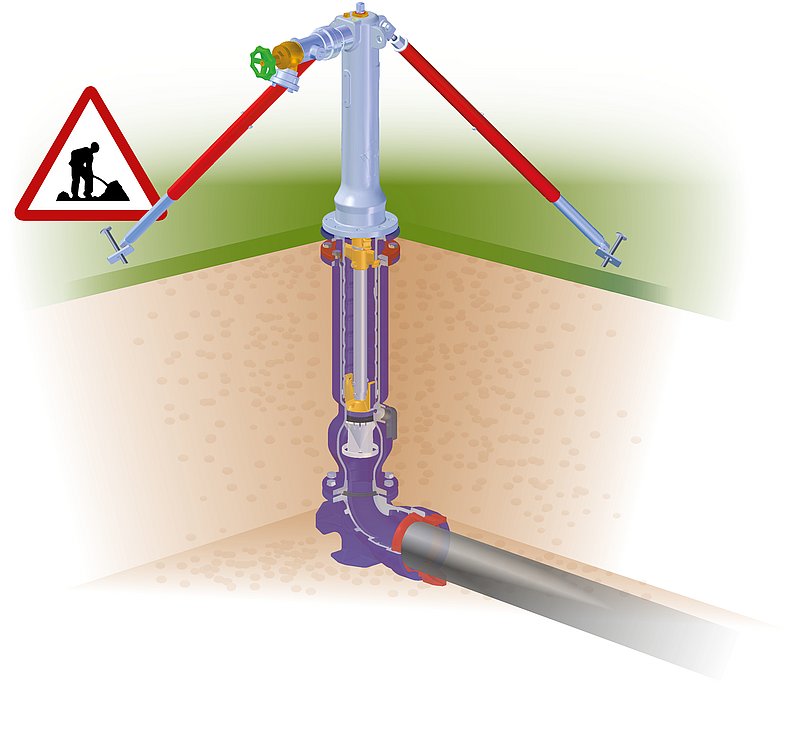

HINNI UNDERGROUND HYDRANT

First height adjustable underground hydrant with SVGW-certification, with dual shut-off.

Every Hinni underground hydrant is convertible thanks to the underground extension fitting.

2002

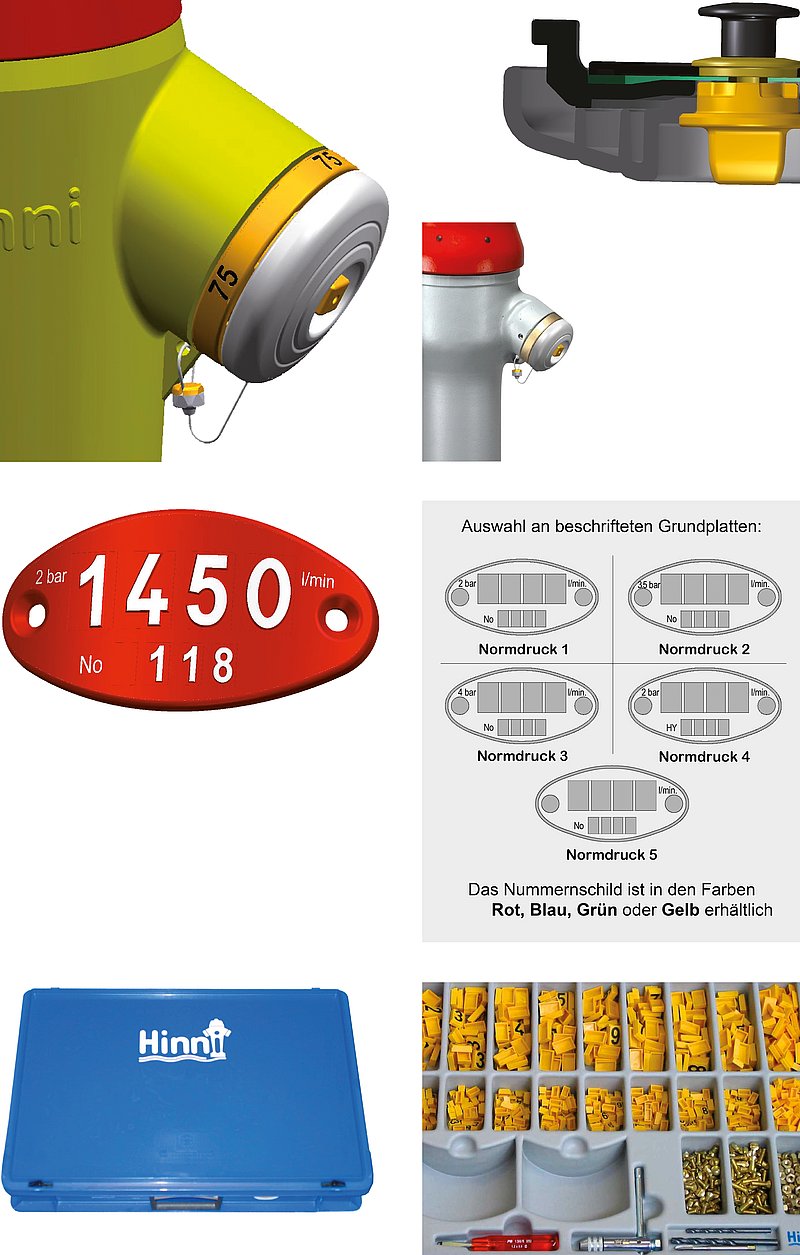

SIGNALISATION AND SAFE USAGE

Signalisation thanks to modular hydrant numbering system.

Secure closing cap with sunken-in square bolt (cannot be opened by hand).

2001

HINNI-LOWER SECTION WITH DUAL SHUT-OFF

The first lower section of a hydrant with dual shut-off which can be dismantled under full water pressure and with SVGW license.

- Radial sealing main valve with protection from water pressure

- Without residual water

1996

HINNI-UPPER SECTION MODEL 6006

The first upper section hydrant with one hose connection (Storz 75) and SVGW license.

- Application of GGG (ductile cast iron) and enamalation of water leading cast surfaces: entry bend, lower section parts, upper sectionparts

- Exchangeable seals throughout

SEALING MATERIAL

Change from NBR to EPDM sealings

1995

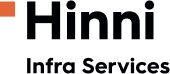

HINNI-Pillar Hydrant MODEL 6000

The first pillar hydrant with 2 hose connections Storz 55/75 (changeable, with 3‘‘ thread) with SVGW-certification.

- Application of GGG (ductile cast iron) and enamelling of water leading cast surfaces: entry bend, lower section part, upper section part

- Exchangeable seals throughout.

HINNI-LOWER SECTION STANDARD

The LS-ST – first height adjustable lower section of a hydrant with SVGW-certification, and a telescopic main valve rod

- Suspension screw with predefined breaking point – a new concept for the predefined breaking points of hydrants

- Spare parts in stainless metal and INOX- compatible for hydrants built since 1935.

1990

ESTABLISHMENT OF HINNI AG

Acquisition of the patent and the equipment necessary for the repair of hydrants while under pressure by Hans-Ruedi Hinni.

Definition of processes for the maintenance of hydrants:

- Control – maintenance ofhydrants (HYKO)

- Repair under pressure (REVO)

HINNI HYDRANT SPARE PARTS AND RECYCLING

Beginning of spare parts production for all hydrant models since 1896, and the beginning of hydrant recycling.

1982

HYDRANT-REPAIR

Development and patent application for a waterlock device for the repair of hydrants under full water pressure. Developed by Hans-Ruedi Hinni, former well master in Suhr, and a resident of Seon.